Diving deep into the heart of the Volvo EC210 excavator, we're focusing on the vital role its Vehicle Electronic Control Unit (VECU) plays. This powerful module is responsible for managing and coordinating a vast network of signals, ensuring optimal performance, safety, and efficiency. From precise adjustment of hydraulic functions to monitoring engine readings, the EC210 VECU is a crucial element in maximizing the machine's capabilities.

- Unveiling the intricate workings of this advanced system provides valuable insights into how modern excavators operate at their best.

- We'll explore core components that make the EC210 VECU a leader in its field.

- Moreover, we'll delve into practical applications and real-world scenarios where the VECU's performance is critical.

Get ready to uncover the secrets of this vital machine component!

Understanding the Volvo EC210 VECU System

The Völsung EC210 excavator is a powerful and versatile machine renowned for its capability. A crucial component in this industrial machinery is the VECU system, which stands for the Vehicle Electronic Control Unit. This sophisticated digital system serves as the main processor for managing a range of vital functions within the excavator.

- Regulating engine parameters

- Observing hydraulic circuits

- Facilitating operator commands

- Guaranteeing overall machine functionality

By efficiently linking various instruments and components, the VECU facilitates the operator to perform precise actions while preserving optimal output. Understanding the workings of this complex structure is essential for any engineer working with the Volvo EC210 excavator.

Volvo's EC290 Excavator : Power and Performance in Action

On any construction site, the requirements for power and performance are high. The Volvo EC290 excavator is designed to exceed these expectations with its robust drivetrain and efficient hydraulic system. This reliable machine delivers outstanding results in a wide range of applications, making it a favorite choice for contractors across the globe.

- Users will appreciate the EC290's ergonomic cab, which offers a panoramic view of the work area.

- Cutting-edge technology are integrated into the EC290 to enhance operator productivity and fuel efficiency.

The Volvo EC290's strong build ensures it can withstand the most rigorous working conditions.

Simulating Volvo Truck ECU Behavior

Developing comprehensive test scenarios for sophisticated Volvo truck Electronic Control Units (ECUs) often presents a challenge. Traditional methods involving physical testing can be time-consuming and expensive. To address this, engineers are increasingly turning to simulation tools to accurately replicate ECU behavior in a virtual environment. These simulations allow for the testing of diverse scenarios, such as fault injection, diverse driving conditions, and software updates, without the need for real-world trucks. By leveraging sophisticated mathematical models and algorithms, simulation platforms can accurately capture the intricate workings of Volvo truck ECUs, providing valuable insights into their performance and reliability.

- Simulations offer a cost-effective alternative to physical testing.

- Virtual environments allow for rapid iteration and experimentation.

- Engineers can test a wide range of scenarios, encompassing extreme conditions.

This accelerates the development process and results in more robust and reliable Volvo truck ECUs.

Analyzing Volvo VECU Problems

When your Volvo's Vehicle Electronic Control Unit (VECU) starts acting up, it can lead a range of frustrating issues. Luckily, with a systematic approach and the right tools, you can often identify the culprit and get things running smoothly again. This guide will walk you through common Volvo VECU problems and offer step-by-step repair tips to help you address these issues effectively.

Start by observing the symptoms your vehicle is exhibiting. Is the engine stalling? Are there any warning lights on the dashboard? Once you have a clear understanding of the problem, you can begin to identify the potential cause.

- Consult your Volvo's owner's manual for specific information about the VECU and common fault codes.

- Leverage a diagnostic scanner compatible with Volvo vehicles to retrieve any stored error codes.

- Assess the wiring harness and connectors associated with the VECU for signs of damage, corrosion, or loose connections.

If you're e-ecu volvo unsure about any aspect of the troubleshooting process, it's always best to seek advice to a qualified Volvo mechanic.

Advanced Volvo Excavator Control Systems

Volvo Construction Equipment is renowned for its commitment to innovation and delivering advanced solutions for the construction industry. A key aspect of this commitment is their development of sophisticated excavator control systems. These systems are designed to improve operator efficiency, reduce fuel consumption, and maximize overall performance.

Volvo's advanced excavator control systems often incorporate technologies such as GNSS for precise positioning, pneumatic proportional controls for smoother operations, and easy-to-operate interfaces that streamline the operator's workflow.

- Furthermore, these systems often include security features like obstacle detection and automatic shutdown functions to mitigate potential threats on the construction site.

- Furthermore, Volvo's excavator control systems are continuously being improved through software updates and new developments.

Scott Baio Then & Now!

Scott Baio Then & Now! Mason Gamble Then & Now!

Mason Gamble Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Barbi Benton Then & Now!

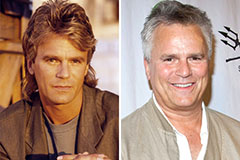

Barbi Benton Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!